Rehydration of katoite as a layered double hydroxide: an in situ study

DOI:

https://doi.org/10.21809/rilemtechlett.2021.130Keywords:

Alternative cement, Calcium aluminates, Katoite, Layered double hydroxide, RehydrationAbstract

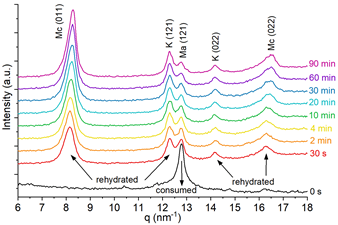

Calcium aluminate layered double hydroxides (Ca-Al LDHs) constitute a considerable part of cementitious waste fines. Although cementitious waste fines have proven to be recyclable by thermal treatment at moderate temperatures (400–700 °C), understanding how each phase rehydrates and contributes to the binding properties of rehydrated cementitious materials is still necessary. In this study, the de(re)hydration of katoite is investigated through in situ techniques, and its applicability as an alternative cement or supplementary cementitious material (SCM) is discussed. The research employed X-ray diffraction, isothermal calorimetry, in situ wide-angle X-ray scattering (WAXS), and rotational/oscillatory rheometry. Katoite synthesized by a mechanochemical process was dehydrated at 400 °C, producing mainly mayenite. During rehydration, calorimetry presents high heat production in the first minutes. WAXS shows prompt recovery of katoite and increasing formation of monocarboaluminate (Ca-Al LDH) after 30 s of rehydration. The findings confirm the direct association between rapid heat release and phase reformation. Rehydrated pastes present a high yield stress and an increasing storage modulus, indicating rapid binding properties. The consolidation is also correlated with cumulative heat and monocarboaluminate formation. The results indicate the potential of calcined katoite for use as rapid set alternative cement or SCM.

Downloads

Published

How to Cite

Issue

Section

License

Authors retain copyright of the articles published in RILEM Technical Letters and grant the journal the right of first publication with open access. The work is simultaneously licensed under Creative Commons Attribution 4.0 International License (CC BY 4.0) that allows others to share and adapt the work under the following terms: 1) a proper attribution is given in a form of a reference to the original work's authorship and initial publication in RILEM Technical Letters (bibliographic record with the DOI link); 2) a link to the license is provided; 3) the changes (if any) are indicated.