Improving Concrete Toughness by Aggregate Arrangement

DOI:

https://doi.org/10.21809/rilemtechlett.2020.109Keywords:

Casting, Coarse aggregate, Fracture toughnessAbstract

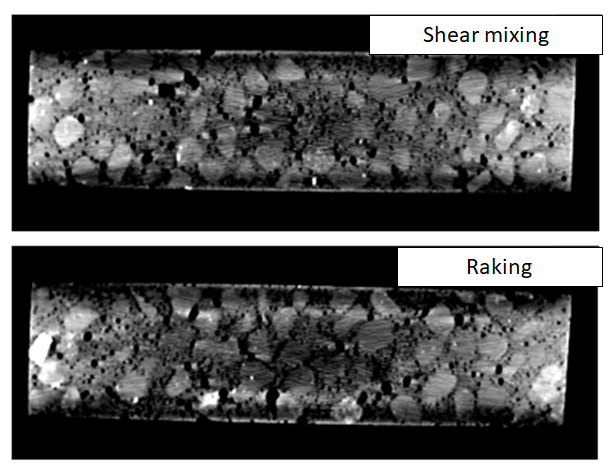

The focus of this research is to address the following open question: Can we engineer the distribution of coarse aggregate in concrete to improve crack growth resistance? A finite element study of aggregates distributed in a notched 3-point bending concrete sample shows that the stress field in front of the crack tip and in the entire concrete beam is carried differently when the aggregate is arranged in a more orderly manner. Based by this, the impact of coarse aggregate arrangement is confirmed experimentally. Fracture toughness is determined from notched 3-point bending samples prepared from the same mix with three types of casting approaches: One following ASTM C31, and two following the standardized casting method with raking and shear mixing to arrange particles in a more ordered manner. To evaluate the impact of these added casting steps to alter aggregate arrangement, X-ray computed tomography (XCT) data is collected of the particle positions for statistical analysis. XCT data shows that added raking and mixing during casting adjusts the arrangement of coarse aggregate with respect to each other in a systematic manner. The mechanical tests show increased toughness can be achieved when raking and shear mixing steps are added following the ASTM C31 casting process.

Downloads

Published

How to Cite

Issue

Section

License

Authors retain copyright of the articles published in RILEM Technical Letters and grant the journal the right of first publication with open access. The work is simultaneously licensed under Creative Commons Attribution 4.0 International License (CC BY 4.0) that allows others to share and adapt the work under the following terms: 1) a proper attribution is given in a form of bibliographic record with the DOI link directing to RILEM Technical Letters; 2) a link to the license is provided; 3) the changes (if any) are indicated.